Not Find Exactly What You Need?

Advance Search

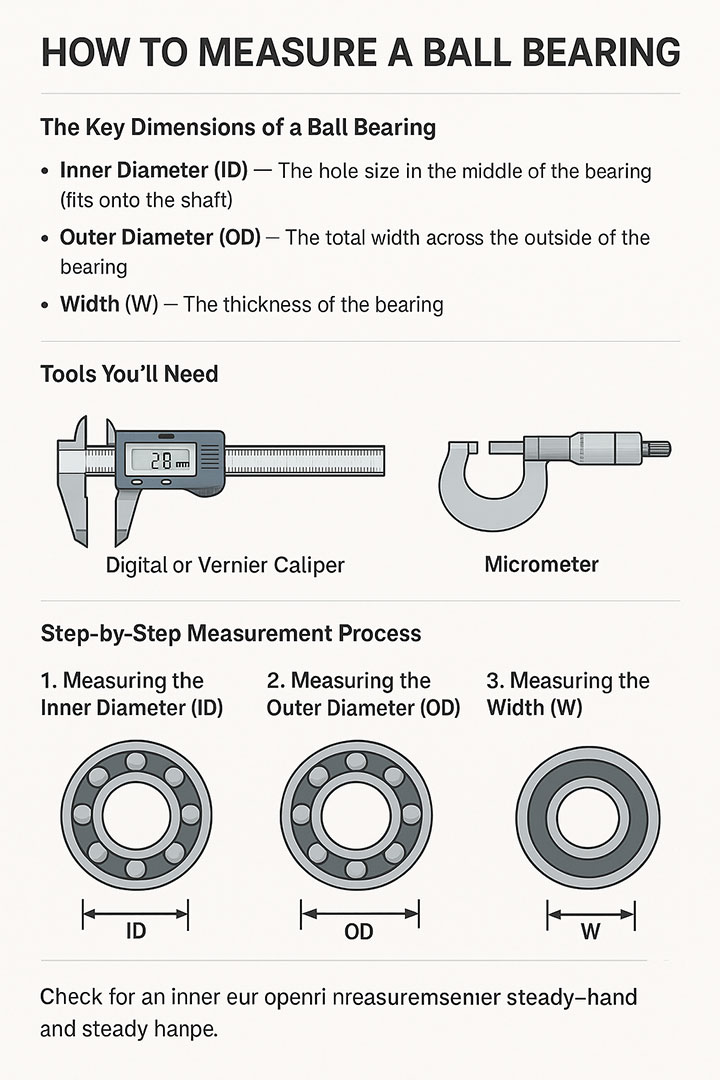

Replacing a worn-out bearing, verifying specifications, or troubleshooting a machine, having the knowledge of how to measure a ball bearing correctly is essential. Ball Bearings might look small and simple, but accurate measurement prevents premature wear, ensures you get the right fit, and saves you from costly mistakes and downtime.

Here, in this post, we’ll break down the process of measuring a ball bearing step by step.

Each bearing has three primary dimensions that you’ll want to measure:

These measurements together, will help you identify the correct bearing or confirm the size in a parts catalog.

1. Measuring the Inner Diameter (ID)

For example, an ID of 20 mm means the ball bearing will fit a 20 mm shaft.

2. Measuring the Outer Diameter (OD)

Place the caliper jaws around the outside edge of the bearing.

Make sure you measure across the widest point of the bearing.

Write down the result, this tells you the housing size required.

3. Measuring the Width (W)

Hold the caliper jaws against the flat sides of the bearing.

Measure the distance between the two parallel faces.

This is the width or thickness of the bearing.

Extra Tips

Check for wear: If you’re measuring a used ball bearing, then keep in mind that any wear might slightly reduce the size.

Note the bearing number: Most, if not all, bearings are stamped with a reference number (e.g., 6205). After you finish measuring, you can cross-reference this number in a catalog.

Metric vs. Imperial: Ball Bearings come in both measurement systems. Check your unit system when ordering.

Quick Reference Example

Example measurements:

This corresponds to a standard 6205 bearing (which is a very common type).

Final Thoughts

Measuring a ball bearing isn’t complicated, but doing it carefully makes the difference. With just a caliper and a steady hand, you can identify nearly any bearing size and ensure your machinery keeps running smoothly.

Search For Products By Keyword, Category Or Subcategory. Check one or more categories or enter up to 10 keywords separated by spaces.